Proprietary Software

- Home

- Stockpile Science

- High Performance Computing

- Proprietary Software

Advancing Discovery Science and Innovation

LLNL’s large-scale codes incorporate multiform physics and engineering to model and simulate incredibly complex systems that would be too expensive, impractical, or impossible to physically demonstrate.

Simulating a wide range of applications where several different physical phenomena are closely coupled

About

ALE3D is a 2D and 3D multi-physics numerical simulation software tool using arbitrary Lagrangian-Eulerian (ALE) techniques used not only by LLNL staff, but by other programs across the nuclear security enterprise and Department of Defense.

The code uses finite element and finite volume formulation to model fluid and elastic-plastic response on an unstructured grid.

Additional ALE3D features include heat conduction, chemical kinetics and species diffusion, incompressible flow, wide range of material models, chemistry models, multi-phase flow, and magneto-hydrodynamics for long (implicit) to short (explicit) time-scale applications.

Distribution

ALE3D is a limited access code for use by DoD and DOE laboratories and their contractors with individual Use Agreements. Please contact ale3d-help [at] llnl.gov (ale3d-help[at]llnl[dot]gov) to find out if you are qualified to attend and to be sent an invite as soon as the registration website opens.

We also distribute ALE3D4I, a special version of ALE3D and is available for U.S. companies and academics. More information on licensing can be found here.

ALE3D INTRODUCTORY CLASS via Microsoft Teams

This introductory class covers the basics of running the code and describe some of the theory behind its various physics modules. There is a mix of lecture and hands-on training during the five days. The target audience are those who have performed some computational modeling. Some experience running ALE3D is helpful, but not required. Users must have a valid, current license. LLNL employees must have a valid LC account and group ale3d_au. Please see attached draft agenda for additional detail on the schedule.

When/Fees

July 8 – 12, 2024 - $1350

Download the course agenda here.

Register for Introductory Course

ALE3D ADVANCED CLASS via Microsoft Teams

This is an Advanced Class in the use of ALE3D. While many of the topics we cover are presented in the introductory course, this class will discuss these topics in much greater detail. The target audience are those who are users of ALE3D, and previous attendance of the Introductory ALE3D course is highly encouraged. Registration will be on a per-module basis so attendees can sign up for one or all of the modules at the time of registration.

Users who are licensed, and on the waitlist, will be given priority once registration opens. If you wish to be put on the waitlist, please email ale3d-help [at] llnl.gov (ale3d-help[at]llnl[dot]gov).

When/Fees

Spring 2025 - TBD

- Module 1 – February 12 & 13 – $1000

- Meshing

- Module 2 – February 14 & 15 – $1000

- Advection

Week 2 - Draft Agenda

- Module 3 – February 26 – $500

- Embedded Grids/SPH

- Module 4 – February 27 – $500

- Materials

- Module 5 – February 28 – $500

- Implicit Multiphysics

Week 3 - Draft Agenda

- Module 6 – March 11, 12 & 13 – $1500

- High Explosives

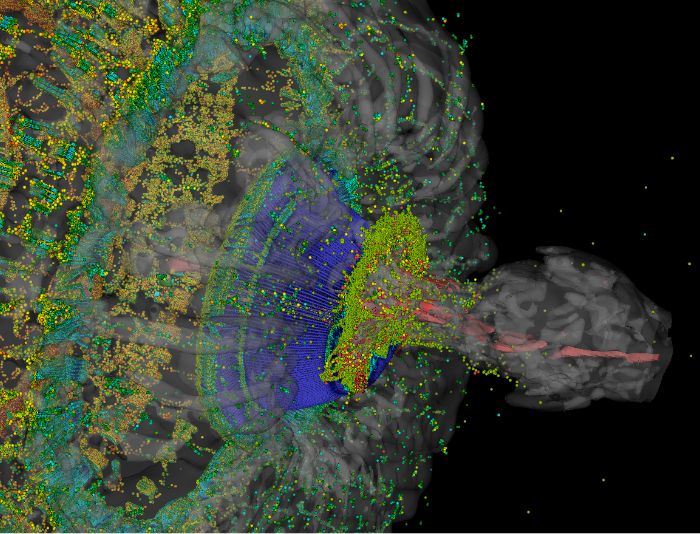

ALE3D Applications

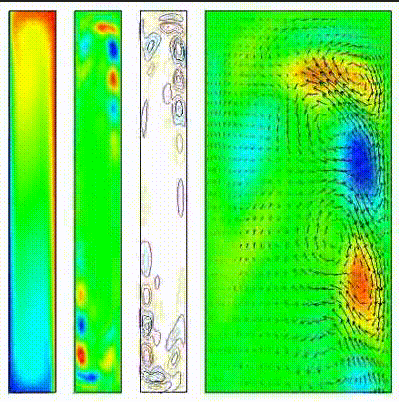

Detonation, Deflagration, Convective Burn

ALE3D can model the detonation, deflagration, and convective burn processes associated with the energetic response to thermal and mechanical stimuli of both high explosives and propellants.

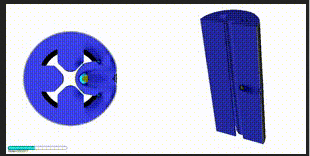

Rocket Motor Impact

NATO fragment impacting HPP rocket motor at 1.0 and 2.6 km/s. The PERMS (propellant energetic response to mechanical stimuli) model is used to predict the impact response of the propellant to the NATO fragment. Watch the complete simulation.

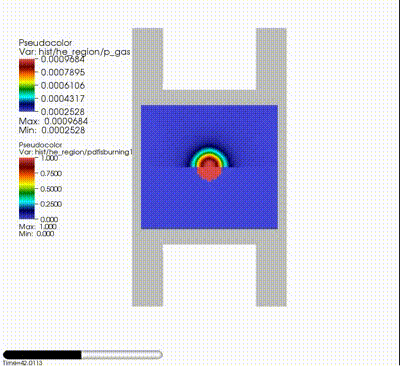

Convective Burning

Explicit Hydrodynamics

Enforces conservation of momentum using the Finite-Element Method. Problems can be solved in ALE3D using the Lagrange+Remap approach. Such formulation allows the user the option to run in a variety of modes from Fully Lagrangian to Fully Eulerian.

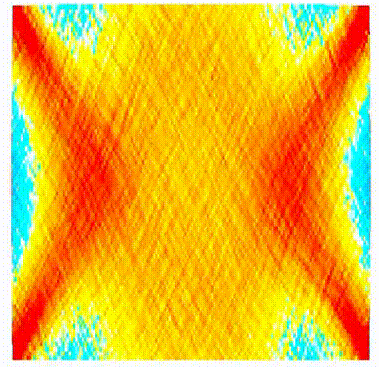

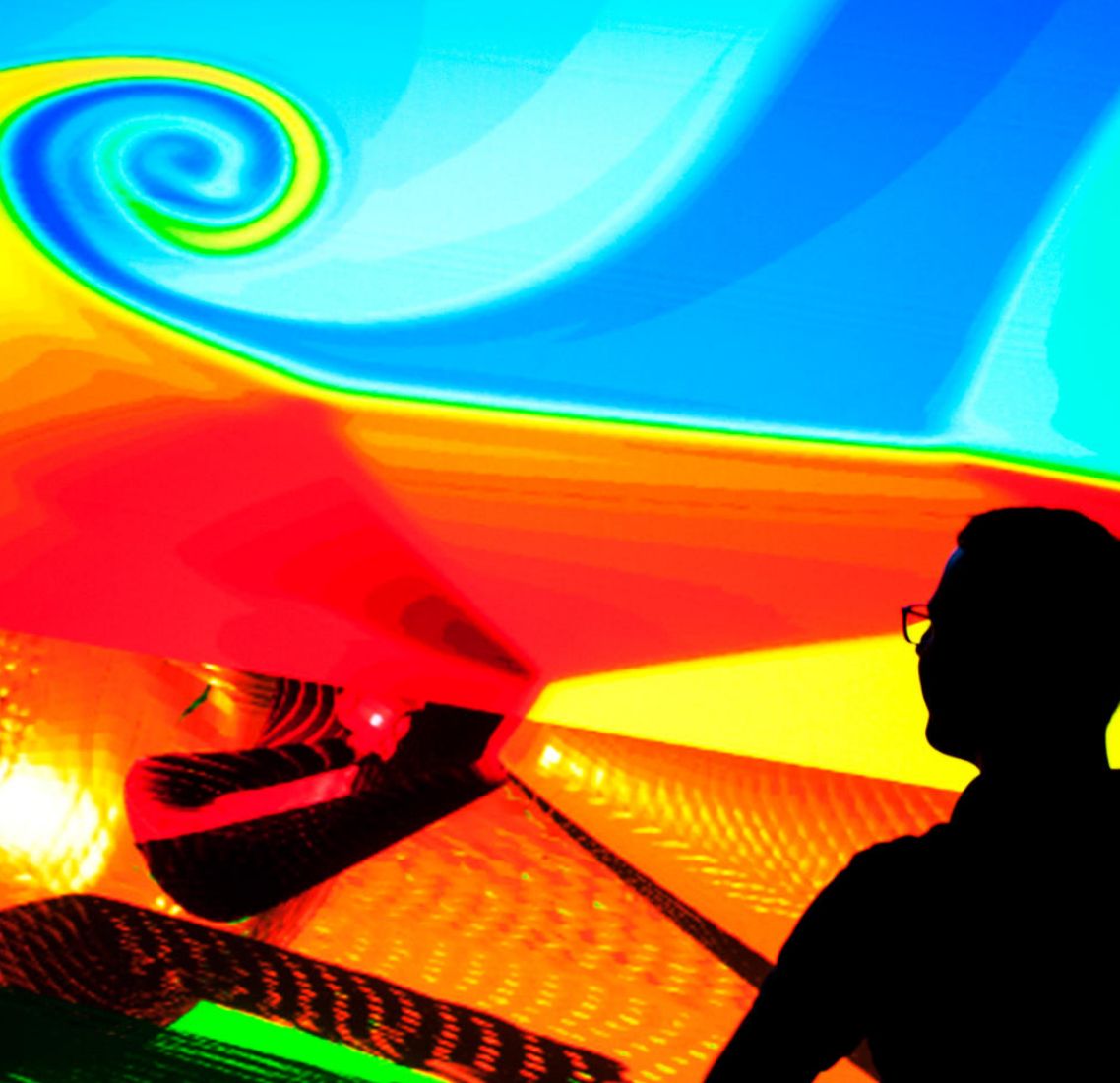

Contours of temperature field using ALE3D explicit hydrodynamics simulating a polymer-bonded explosive (PBX) explosion in a confined space. Ritchmeyer-Meshkov instabilities are captured at the shock interface due to density gradient. Watch the complete simulation.

Fracture and Fragmentation

The Arbitrary Lagrangian-Eulerian capabilities in ALE3D provide a robust solution for high velocity impact problems while other parts of the simulation can be kept Lagrangian to provide an accurate representation of surfaces and material deformation.

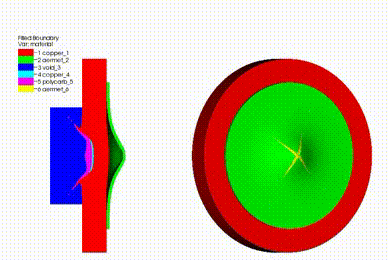

In this simulation, a scored steel plate sitting against a copper buffer is impacted by a copper flyer backed by polycarbonate. The impulse launches the steel plate from the buffer, and the resulting biaxial stretching causes the plate to fracture. The fracture occurs preferentially along the score lines. Watch the complete simulation.

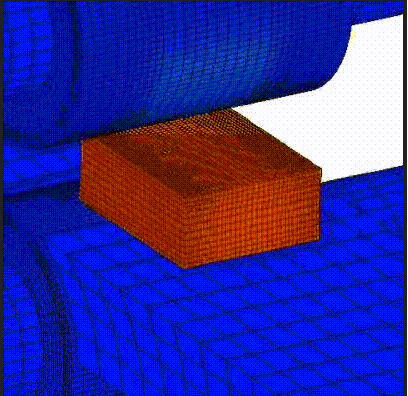

Heat Transfer

ALE3D is involved in process modeling for the aluminum manufacturing industry. This picture shows a simulation of several passes of a hot aluminum slab through cooled steel rollers. The plotted temperature contours show heat transfer from the slab to the rollers, which can be important to stress relaxation rates within the aluminum. The simulation also utilizes ALE3D's capabilities for slide surfaces with friction and thermal contact resistance, in addition to employing sophisticated damage evolution material models.

One of the principal forming processes for aluminum is the hot rolling of ingots into thick slabs and further rolling to form plate and sheet material of various thicknesses. Multiple passes in a reversing rolling mill of a hot slab are required to produce semi-finished aluminum plate. However, the large deformations encountered while rolling may lead to failure modes that result in loss of part or even the entire slab. The formation of defects within the plate, such as edge cracking, delamination, alligatoring (center splitting near the front and rear), and the formation of undesirable rolled end shapes, all lead to product losses.

Processing parameters could be chosen that improve product yield if the slab material response to the hot rolling process were sufficiently well understood. We have worked with a major aluminum manufacturer to develop models that:

- Predict temperature, stress, strain, and damage evolution of slab material as it evolves through multipass rolling

- Determine the effect of initial slab shape and rolling pass schedule on fracture and internal product integrity

- Demonstrate the utility of a numerical model as a forming process optimization tool

This movie shows the result of several passes of a hot aluminum slab through cooled steel rollers. The plotted temperature contours show heat transfer from the slab to the rollers, which can be important to stress relaxation rates within the aluminum. The simulation also utilizes ALE3D's capabilities for slide surfaces with friction and thermal contact resistance, in addition to employing sophisticated damage evolution material models. Watch the complete simulation.

Implicit Hydrodynamics

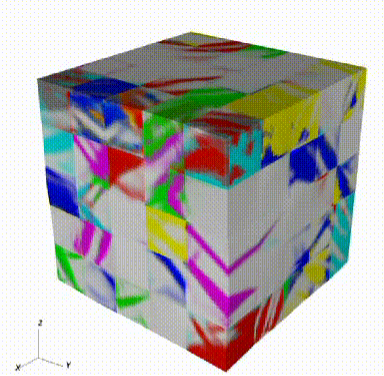

Twin domain formation during large strain compression of an idealized magnesium polycrystal. Watch the complete simulation.

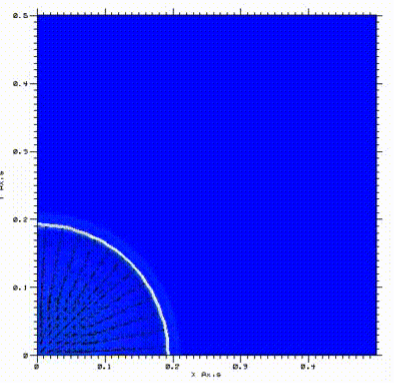

Incompressible Flow

The incflow model solves the incompressible Navier-Stokes equations using the finite-element method. It uses an implicit projection time-stepping scheme. It is appropriate for long time scale, low Mach number flow problems dictated by viscous effects. The model can be coupled to the heat transfer package for the computation of thermal convection problems. Watch the complete simulation.

Lagrangian Particulate Model

The particulate package tracks individual discrete particles through the computational domain. This model is useful for very dilute multi-phase flow problems. Watch the complete simulation.

Magneto-Hydrodynamics (MHD)

The MHD module solves the transient magnetic advection-diffusion equation, magnetic forces are coupled to hydrodynamics and Joule heating is coupled to heat transfer.

A simulation of a physical experiment uses large magnetic fields to compress a thin wall aluminum tube. The geometry consists of a robust steel outer tube and a 0.030-in. inner aluminum tube; the tubes are connected together at one end and connected to a header at the other end. In the physical experiment this device is connected, via 12 cables, to three 10-kV capacitor banks which are discharged simultaneously. In the ALE3D simulation, the capacitor bank and associated cables are modeled by an RLC circuit which is coupled to the Magneto Hydrodynamics (MHD) partial differential equations (PDEs). A large magnetic field exists in the space between the tubes, resulting in a large 'magnetic pressure' that will compress the inner tube.

The simulation exercises the coupling of magnetic fields with explicit hydrodynamics. The thin aluminum tube is constrained to be Lagrangian, but in the air region mesh relaxation is allowed. Since the temperature rise is small, heat transfer is ignored. In the physical experiment both strain gauges and photonic doppler velocimeters were used to measure the deformation, and ALE3D results correlated quite well with this data.

Multiphase Model

The multiphase model allows the computation of flows involving multiple dispersed materials (or phases) where each phase is treated as a continuum. It uses a cell-centered Godunov-type finite-volume scheme. Each phase possesses its own distinct velocity and state data. Watch the complete simulation.

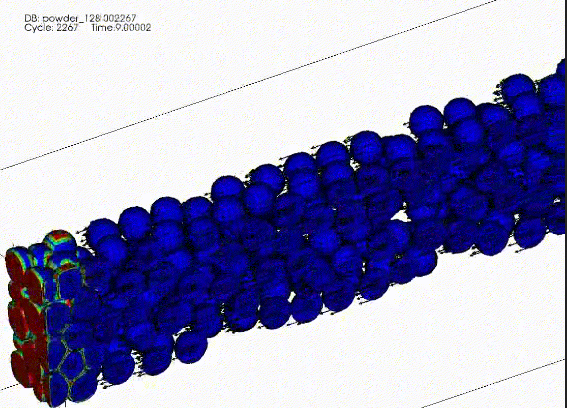

Powder Compaction Calculations with ALE 3D

Plastic strain contours and velocity vectors for aluminum powder compaction inside a rigid box. Watch the complete simulation. Watch the complete simulation.

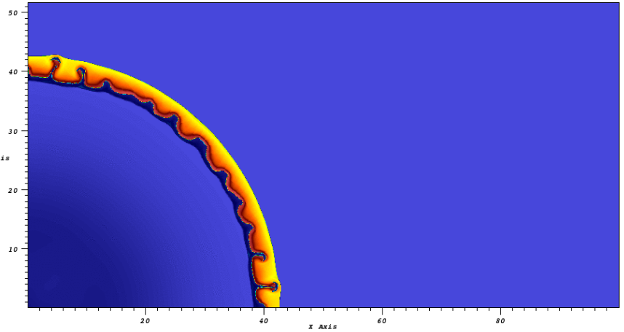

Structural

The ALE (Arbitrary Lagrangian-Eulerian) framework allows for a fully-coupled fluid-structure interaction approach when modeling such complex behavior as a high explosive detonated in contact with a reinforced concrete column. Structural elements, such as beams and shells, have also been implemented for structural applications.

The ALE (Arbitrary Lagrangian-Eulerian) framework allows for a fully-coupled fluid-structure interaction approach when modeling such complex behavior as a high explosive detonated in contact with a reinforced concrete column. Structural elements, such as beams and shells, have also been implemented for structural applications.

This is an example of a fully-coupled fluid-structure interaction blast effects simulation. This simulation shows a small high explosive charge detonated in contact with a reinforced concrete column. The orange material is the high-explosive products. Completely damaged concrete is shown in red and undamaged concrete is shown in blue.

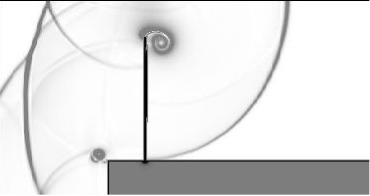

Void Collapse in Solids

Temperature field generated from void collapse in a solid material. Explicit Hydro simulations capture formation of primary jet and secondary shock propagation. Watch the complete simulation.

Download a complete list of ALE3D presentations and papers here.

Contact

For questions regarding ALE3D, please email: ale3d-help [at] llnl.gov (ale3d-help[at]llnl[dot]gov)

Predicting the performance of ideal and non-ideal high explosives and explosive formulations

About

Cheetah, an LLNL thermochemical computer code, is a convenient and accurate physics- and chemistry-based computational tool for predicting the detonation velocities and energy release properties of energetic materials such as explosives, propellants, and pyrotechnics.

Cheetah employs advanced concepts and theories of fluids and solids at high pressures and temperatures to model the thermodynamics of explosion products that result from the detonation of modern condensed, energy-dense explosives. The results can be used for materials design, performance predictions and formulation optimization, as well as safety analyses, accident forensics, and even to study homemade and terrorist devices. SD makes particular use of the Cheetah database, which currently includes a wide range of approximately 1,000 chemical ingredients and products.

The science base of the Cheetah code is being updated continually to incorporate new theoretical and experimental results relevant for the physics and chemistry of high-pressure and temperature phenomena.

For more information on updates, visit here.

Distribution

Cheetah is not a publicly available code and can only be used by active LLNL employees and our partners in the Department of Defense.

Contact

For questions regarding Cheetah, please email: sbastea [at] llnl.gov (sbastea[at]llnl[dot]gov)

Simulating experiments carried out at NIF and other high-energy-density physics facilities

About

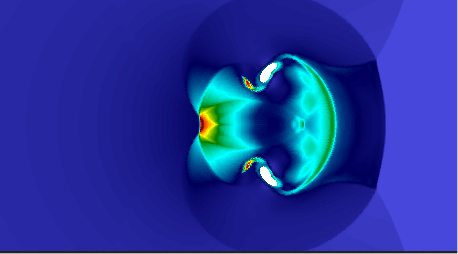

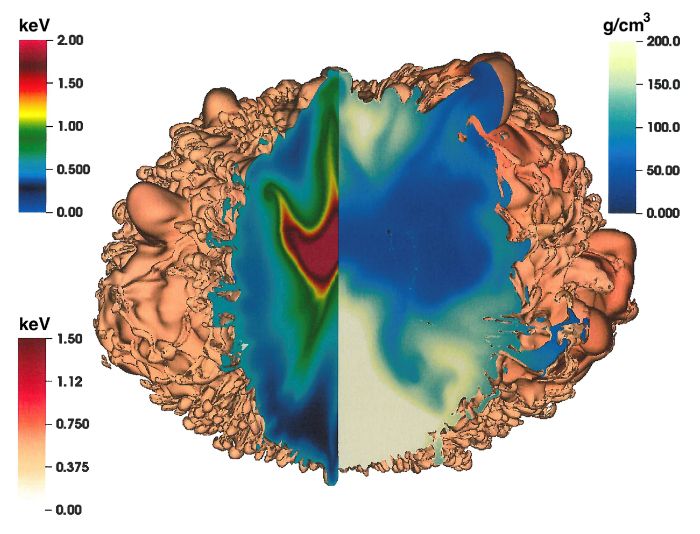

HYDRA is a 2D and 3D multi-physics code used to design and simulate Inertial Confinement Fusion (ICF) and High Energy Density (HED) targets. It is a Lagrangian-Eulerian code based upon a multiblock mesh.

HYDRA has a broad range of physics models useful for simulating indirect drive, direct drive, and magnetic drive targets. These include 3D models for laser ray trace, electron transport, magneto hydrodynamics (MHD) with full Ohm’s law, ion beam transport, radiation transport, thermonuclear burn and burn product transport. HYDRA has a range of capabilities for modelling atomic physics, including inline non-local thermal equilibrium (NLTE) kinetics.

Distribution

HYDRA can be made available to collaborators in ICF research on specific DOE computers.

Contact

For questions regarding HYDRA, please email: marinak1 [at] llnl.gov (marinak1[at]llnl[dot]gov).

Analyzing the dynamic response of solids and structures

About

ParaDyn is a parallel implementation of the DYNA3D engineering simulation code designed to run on distributed memory, message-passing parallel computers. These programs include many Lagrangian finite element functionalities: hexahedral and structural element types, smooth particle hydrodynamics (SPH), over seventy material models, some using related equations of state, and sophisticated contact interface algorithms.

ParaDyn models a range of nonlinear material behavior including elasticity, plasticity, composites, some thermal effects, failure, and rigid body motion. Contact interfaces include frictional behavior, arbitrary interface motion, and material failure transitioning to free particles. So-called "mesh-less" techniques for particle-based spatial discretization remain an area of active R&D.

Distribution

ParaDyn can only be used by LLNL employees and by our collaborators in the Department of Defense.

Contact

For questions regarding ParaDyn, please email: giffin1 [at] llnl.gov (giffin1[at]llnl[dot]gov)

Collaboration Fuels our Innovation

LLNL developers create and evolve software daily.

While some of this software can only be used internally, LLNL still maintains a vast portfolio of open-source projects that includes applications, libraries, compilers, and other tools that can be accessed by GitHub for public use and collaboration.

Building the Next Generation of Codes

The next generation of supercomputing will require significant development of simulation codes, code architectures, and applications development in order to provide leading edge simulations capabilities.

Open and exciting opportunities include:

- Advancing AI, data analytics, machine learning, predictive modeling, statistics, UQ, and more

- Maximizing the efficiency of software development and deployment

- Innovating in new directions for next-generation hardware designs and platform

- Deploying operation integrations in one of the world’s largest HPC data centers

Equal Height Columns - Header Text

Anim pariatur cliche reprehenderit, enim eiusmod high life accusamus terry richardson ad squid. 3 wolf moon officia aute, non cupidatat

Header Text Maximus Across the Entire page to a second line

Nihil anim keffiyeh helvetica, craft beer labore wes anderson